Driver safety is first and foremost for any good race team so the decision was made to install an on-board fire suppression system.

Driver safety is first and foremost for any good race team so the decision was made to install an on-board fire suppression system.

The system is plumbed through the car with nozzles in the cabin and engine bay. While the system comes with a small weight penalty over a traditional extinguisher it will be much more effective in the event of a fire.

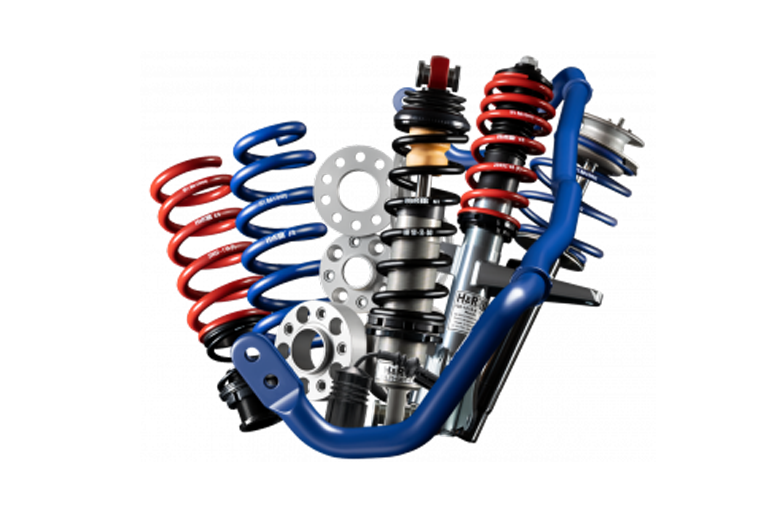

As we mentioned in the WORLD TIME ATTACK CHALLENGE feature, our car this year was much the same as it was last year, bar a few suspension components, engine tweaks, and the most important thing driver safety. We replaced the old worn out suspension arms with a complete new set of Hardrace performance suspension arms and components.

In an effort to save weight and tidy things up in the engine bay, our fabricator Don, sourced a lightweight alternator and made a new, lighter mount. The new setup came in 5kg lighter than the original Nissan alternator and bracket.

A mock up of the original mounting points was made on the fabrication bench which allowed the new bracket to be designed and made off the car.

A new aluminium pulley was machined up to ensure the new alternator worked in the correct RPM range.

Once we got our motor back from Abes Race Engines, we bench mounted it so we could do the final fit up of all the auxiliary components. A lot of effort went into tidying up the hoses and component positioning to give reliability and ensure it was easy to work on once installed in the car.

Our goal with the new motor was to have a much more responsive engine but with use-able power.

Custom heat shields were made up to protect the turbo- oil, and water feed lines.

The cooling system was simplified with the removal of ports and lines from removed components.

Quick zip across the warehouse.

Ready to be dropped in, two days before World Time Attack…

Ready to be dropped in, two days before World Time Attack…

We got the motor back in the car, and sent it over to Tunehouse to have its first start and run in.

After Jim had run the motor in, it was time for a tune! Jim spent a lot of time on it, working late into the night to get the tune perfect.

At around the 2 am, 380kw at the hubs flashed up on the Dyno screen with a healthy looking power curve. Car was ready to run, and we where ready for bed!

Photography by SELECTNINE.